ABOUT US

当前位置: > ABOUT US

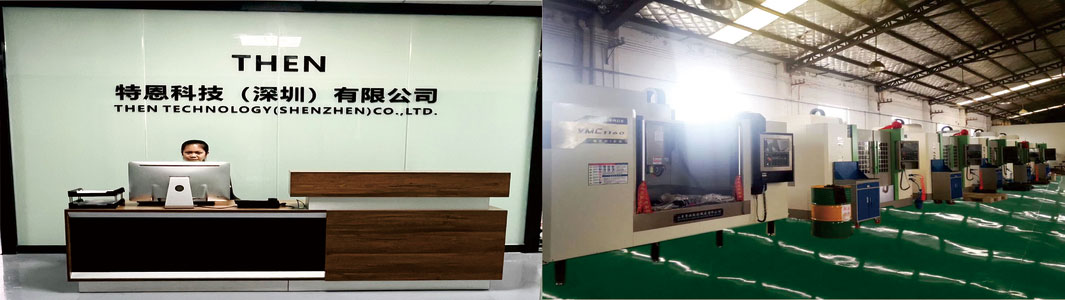

THENTECH is a professional equipment service company, mainly engaged in

SEMICONDUCTOR/PV/PCB/PANEL/GLASS/Environmental Protection and Other industries

equipment spare parts & peripheral equipment for development, production, sales and

technical services also import & export business with own right.

Main business: SC、UCE、SCHMID、RENA、ATOTECH、MACDERMID、HOLLMULLER、AMAT、ACM、LAM、PNC、NAURA、PIOTECH、AMEC、MATTSON、TEL、SCREEN、KINGSEMI、KUTTLER、MANZ and other plating & wet process equipment spare parts, consumables and peripheral equipment.

Main products: all kind of rollers, gear wheels, drive shafts, shaft sleeves, fixed sleeves, couplings, nozzles, jet discs, dry devices, filters, filter housings, filter cartridges, filter elements and other processing parts; and a variety of motors, pumps, blowers, cylinders, valves, liquid level sensors, temperature sensors, pressure sensors, flow meters, heaters, heat exchangers, encoders, controllers and other conventional parts and so on.

Processing mode: OEM/ODM, Sample, Drawing;

Process: machining; grinding; injection; mold processing.

Business purpose: focus on quality & cost

Objective: 100% customer satisfaction

Advantages: the whole factory precision customization

SEMICONDUCTOR/PV/PCB/PANEL/GLASS/Environmental Protection and Other industries

equipment spare parts & peripheral equipment for development, production, sales and

technical services also import & export business with own right.

Main business: SC、UCE、SCHMID、RENA、ATOTECH、MACDERMID、HOLLMULLER、AMAT、ACM、LAM、PNC、NAURA、PIOTECH、AMEC、MATTSON、TEL、SCREEN、KINGSEMI、KUTTLER、MANZ and other plating & wet process equipment spare parts, consumables and peripheral equipment.

Main products: all kind of rollers, gear wheels, drive shafts, shaft sleeves, fixed sleeves, couplings, nozzles, jet discs, dry devices, filters, filter housings, filter cartridges, filter elements and other processing parts; and a variety of motors, pumps, blowers, cylinders, valves, liquid level sensors, temperature sensors, pressure sensors, flow meters, heaters, heat exchangers, encoders, controllers and other conventional parts and so on.

Processing mode: OEM/ODM, Sample, Drawing;

Process: machining; grinding; injection; mold processing.

Business purpose: focus on quality & cost

Objective: 100% customer satisfaction

Advantages: the whole factory precision customization